Unique recipes, the best ingredients, and the inimitable taste of the great classics. Impossible to resist!

Don't waste time and try our delicious Hazelnut and Milk products, they are perfect for any time of day!

Classic Napolitaner

Minis Napolitaner

Quadratini Napolitaner

Chocolat Napolitaner

Maxi Napolitaner

Gardena Hazelnut

Patisserie Dark Hazelnut

Less Sugar Quadratini Hazelnut

Multigrain Quadratini Hazelnut

Sandwich Hazelnut

Thins Napolitaner

Classic Alpine Milk

Minis Cocoa & Milk

Quadratini Cocoa & Milk

Rose of the Dolomites Milk

Loackini Milk

Don't waste time and try our delicious Cocoa and Vanilla products, they are perfect for any time of day!

Classic Cremkakao

Maxi Cremkakao

Minis Cremkakao

Minis Cocoa & Milk

Minis Double Choc

Chocolat Dark Chocolate

Quadratini Double Choc

Quadratini Dark Chocolate

Quadratini Chocolate

Quadratini Cocoa & Milk

Patisserie Dark Hazelnut

Patisserie Noir Orange

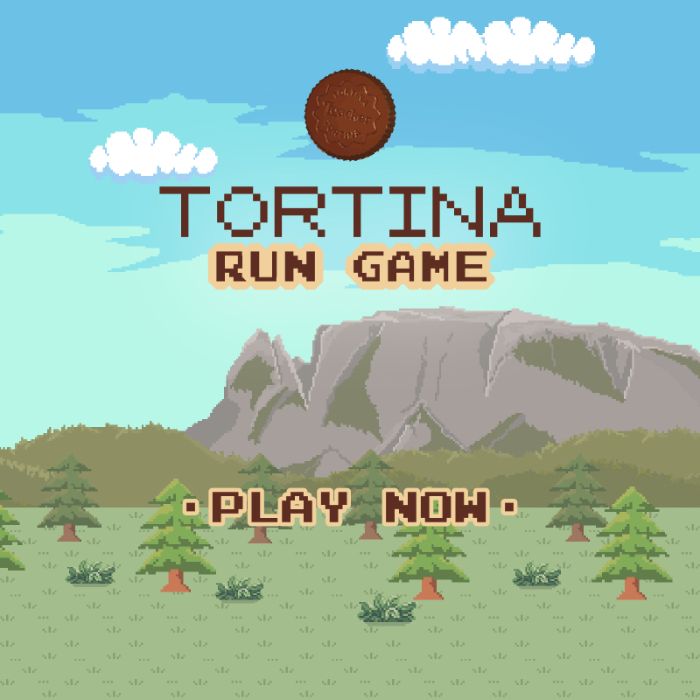

Tortina Triple Chocolate

Tortina White

Tortina Dark

Tortina Mini Dark

Rose of the Dolomites Dark

Loackini Dark

Less Sugar Quadratini Chocolate

Multigrain Quadratini Chocolate

Thins Dark Chocolate

Sandwich Dark Chocolate

Classic Vanilla

Minis Vanilla

Quadratini Vanilla

Maxi Vanilla

Sandwich Milk-Vanilla

Wafer for ice cream Vanilla

Show your affection with a gift that enchants the senses and warms the heart. Share love without words!